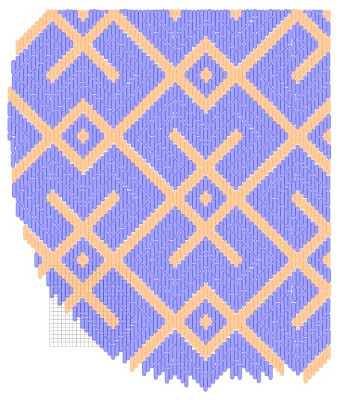

Well I've finished a

tubular threaded in tabletweaving project, and a flat threaded in piece (report soon) and I was trying a few new pieces of tabletweaving equipment, so a report on how well the various bits worked.

Silk thread

Silk threadI used 60/2 silk from the

Handweavers Studio. Actually I used 2 varieties of 60/2 silk and one of 90/3 silk. What do those numbers mean? Well the first number is a rating of how many km to the kg or some imperial equivalent, so bigger numbers mean smaller threads. Since different fibres are different, this number will only work to compare silk to silk, but suffice it to say 60/2 is very small, about the thickness of ordinary sewing machine thread. The second number is the number of plies - how many threads were combined together to make the thread. 2 is a common number now as in medieval times.

90/3 is roughly equivalent in size to 60/2, which is why I used it with the other threads. I really didn't like this thread. It didn't behave like the 60/2 threads, it snapped easier (a weft thread snapping!) and deplies easier and snarls easier when i try and embroider with it. It might be plied in a different direction to the others, or it might be individual thinner threads or something, but this one gave me the irrits.

The 60/2 threads worked like a dream on the tubular band. They didn't snap under the strain, they didn't abrade, snag or have lumpy bits. The fineness wasn't a big problem, just made overall weaving time take longer. The silk is harsher than other fibres, and harder on the hands. I almost got a blister from tugging the weft tight (I was tugging it tighter than normal because this project was tubular). On the second flat piece, the 60/2 silk snapped quite a few times. The snapping partially depended how high a tension I was working at. I think I'd prefer to work with thicker or stronger thread most of the time, but I'd be happy enough to do more work with this thread, especially at lower tension.

Parchment cards

Parchment cards

I bought these last festival. These particular ones are octagonal shaped with 4 holes.

The octagonal shape didn't work well for 4 hole weaving. the cards would slip 1/8th of a turn out of alignment, and on such small cards it was hard to stop them doing so. Octagonal cards might be ok for 8 holed work, but are silly for 4 holed. I want some square holed cards now.

The size is much smaller than I've worked with before, but this wasn't much of a problem. The cards slipped around the edges more easily, but i think with square cards it would be manageable. The threads didn't get caught on the edges of the cards, nor flip over them. It was easier to turn the cards one handed, or with less help from the second hand. The shed was smaller, but manageable. Probably not very good for learners unless they are determined. I ended up keeping the cards closer to the weaving than I normally do, which made locating the shed easier. I was pleasantly surprised at how easily I worked with cards this size, since I'd previously preferred cards twice the size. I think the smaller cards were better for working with the finer materials. Things might be different if I go back to coarse fibres.

The parchment handled well. It was nicely stiff but flexible, subtly better than the cardboard I've used before. The silk didn't noticeably abrade the parchment, nor did the parchment noticeably abrade the silk. That's good - I want the cards to last a while, but I don't want the threads to be cut up. A couple of other people mentioned at the last monthly bash having cards from the same manufacturer and their cards warping in mild humidity. I haven't had this problem, but I haven't had my cards exposed to humidity either. I might also be at an advantage - working with a fine thread might strain the cards less - the others mentioned working with fatter threads and more cards and having the cards curl a bit from the bulk of thread.

Warp spreader

Warp spreaderAs far as I know, I have a unique warp spreader. It's an extremely simple idea I thought up and made based on what I'd seen in period illustrations of band looms. I'll write up the details real soon now. This is my warp spreader's first trial in it's job and it worked just fine. I was worried about the huge quantities of beeswax I poked into the holes, but they worked fine and the threads didn't get waxy feeling. The threads weren't abraded by the spreader either that I could see, even though I had it at pretty high tension occasionally. This still needs to be tested with a weaker thread than silk though.

The warp spreader sat upright on the threads by itself, as long as my tension was moderate. The warp spreader helped keep my cards separated from each other - they never flipped over each other once. The spreader did reduce the amount of space I could work when weaving - I need a longer loom to make this practical. When the weaving got too close to the spreader, the cards floated separate from each other, making them harder to turn as a pack. Partly to combat this I worked with my cards closer to the weaving than i normally do. I think this is more in line with how period manuscripts display weaving.

I found I could adjust tension a little by tilting my warp spreader from the vertical towards the horizontal in the plane of the weaving. But I also found I could tilt the whole warp up and down the loom on a gentle diagonal to adjust my overall tension too, and that this generally was more effective and easier to adjust.

The warp spreader worked nicely and I think it looks just like in the pictures. (and yes my feet are on top of the bottom support strut of my loom) A success!

KB76F21

KB76F21 The Hague, KB, 76 F 21

Book of Hours (use of Paris)

Paris; c. 1400-1410

Fol. 14r

Mary weaving in the temple

Looking at the large sword beaters in the above pictures has given me another idea that I've been considering. They could be just exaggerated size, but what if that is real size? Why would anyone want such a large and heavy cumbersome object when the small beater I have works fine? And why are they shown holding the beater in the warp as they drop the bobbin through. That could be artistic license too - showing all stages of weaving at once to give an impression rather than a snapshot. For that matter, why is the bobbin shown so large - it must be tricky to get through the shed.

My tentative hypothesis: If you have a narrow shed from small cards, and a wide sword beater, you can turn the sword beater sideways and make the shed as wide as your sword beater. Now you can drop bobbins through easily if they are bigger than your cards, as long as they are smaller than the width of your sword beater.

Opinions? Anyone tried this out? I need to make/obtain a wide sword beater and a fat bobbin to do so myself.